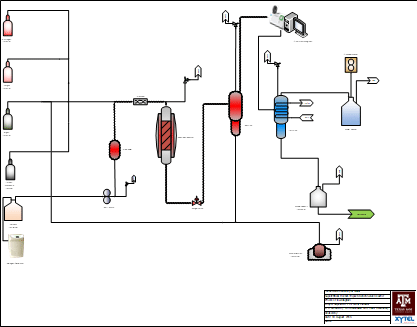

High Pressure FTS reactor Rig

Dr. Elbashir team designed and commissioned the High Pressure & Temperature Supercritical Fluid Fischer-Tropsch Reactor Unit. This unit has been designed to support research activities in GTL (Fischer-Tropsch) and in petrochemicals catalysis. This unit is unique in a way that it provides flexible operation with regards to selecting reactor type; fixed-bed reactor or Continuous Stirred Tank reactor and it is equipped with advanced features in terms of automation that are required for unattended operation and more importantly for safe running of high flow of Carbon Monoxide and Hydrogen at elevated pressures and temperatures. The design work and the orders of the pieces started at TAMUQ while the construction and the detailed work have been conducted by Xytel Inc., a company from South Carolina. The design and the construction of this unit have been funded by QNRF in a 2nd Cycle NPRP and by the Research & Graduate Studies in a special fund for major equipment. RGS also provided

The FTS reactor is divided primarily into two sections: the Feed section and the reactor and separator sections. Other

Gases are supplied to the reactor unit via 4 gas cylinders, at the start of the gas feed section. Solvents may be injected