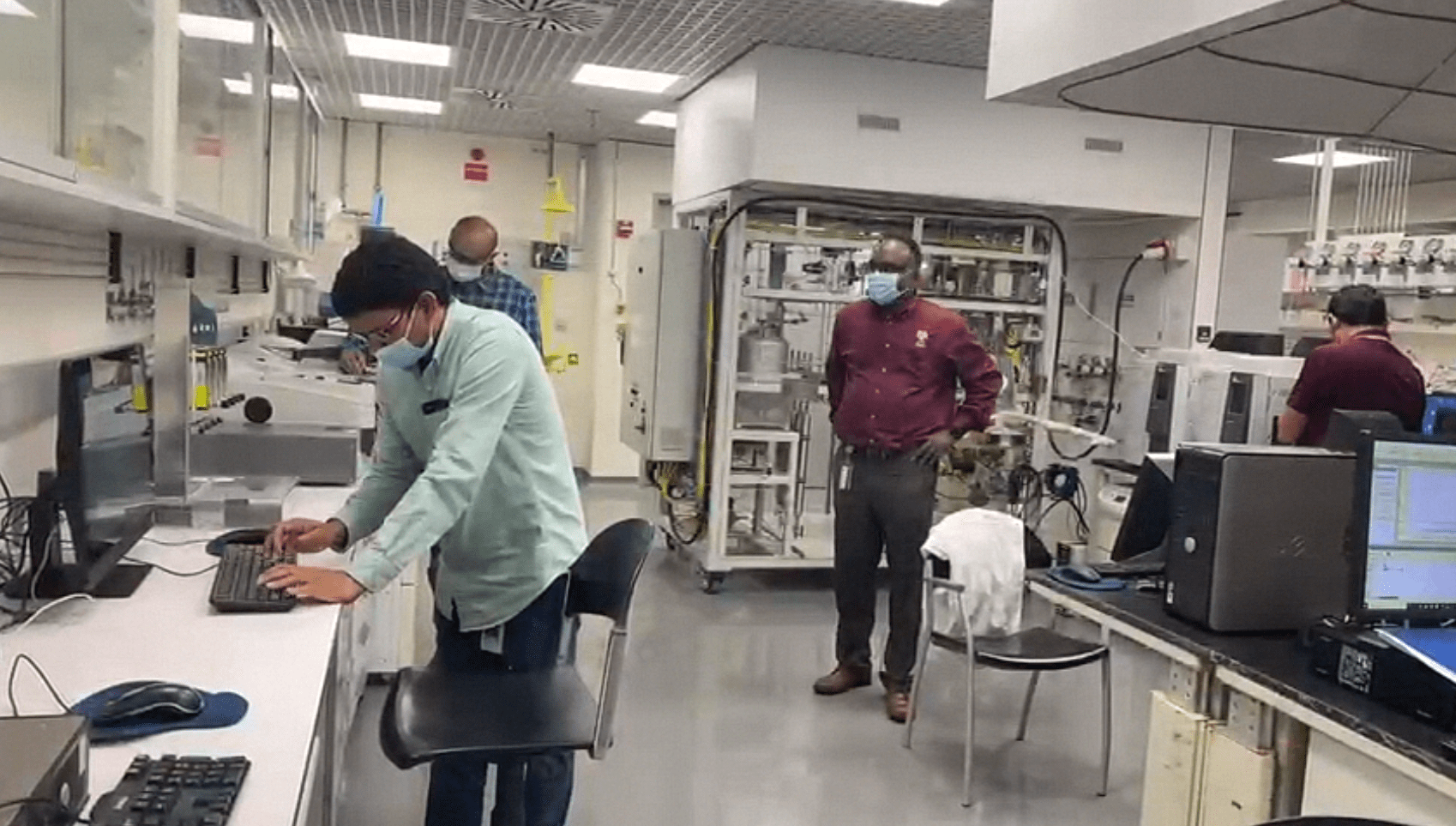

The Elbashir team opened the doors to its newly commissioned Advanced Research Laboratory (ARL) in the Texas A&M Engineering Building.

This state of the art lab houses novel reactors and analytical equipment to develop new processes that convert hydrocarbon feedstock (like natural gas) into ultra-clean fuels and valuable chemicals. We design and test novel catalytic materials and perform online analysis of hydrocarbon products (liquid/gases) by gas chromatography, mass spectrometry, FT-Infrared, and TCD detectors. Other characterization capabilities include measuring porosity, surface area, active site estimation, thermogravimetry, and differential scanning calorimetry. We have even developed novel methods to achieve better results in specific tests. One of the lab’s core focus is to design processes and materials that minimize CO2 emissions from various chemical processes. Therefore, we work closely with industry and other research entities to provide solutions to long-standing challenges in gas conversion processes like the CO2 reforming of methane and Fischer-Tropsch reactions via experimental and computational approaches. Our computational strengths include modeling chemical reactors with COMOSOL and process modeling with ASPEN.

Major catalyst testing/characterization Equipment:

• TGA-DSC

• FTIR/DRIFTS

• GC-FID/TCD

• Online Mass spectrometer

• High pressure (200 bar) fixed bed reactor unit

• Slurry bed (300 bar) unit

• High temperature (850 C)Micro activity catalyst testing unit

• Surface area, pore volume (BET/BJH) measuring unit

• Chemisorption, temperature-programmed catalyst characterization unit

• Other facilities available include gas cabinets (flammable/inert), chemical storage cabinets, two flexible-arm exhaust systems, and a fume hood.

For further details and service inquiries, contact Prof. Nimir Elbashir: nimir.elbashir(at)qatar.tamu.edu

Recent Comments